The middle layer (fir/spruce) is inserted crosswise and glued. By gluing the longitudinal and transverse layers together, ‘working’, i.e. swelling or shrinkage, is reduced to a minimum. This ensures a high degree of dimensional stability.

Surface

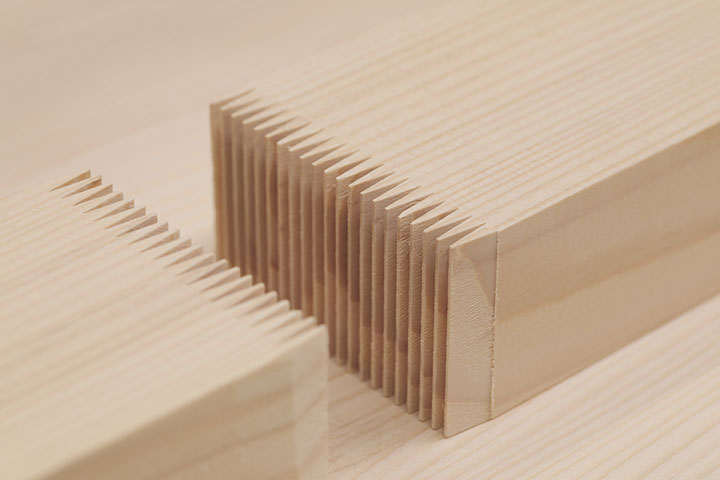

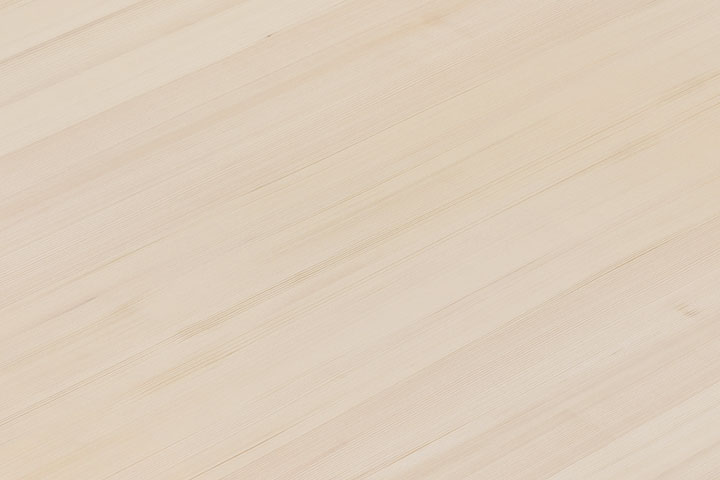

Echtle solid wood panels are made from pure silver fir. However, there is a difference here as to whether the board is glued and pressed from continuous or finger-jointed lamellas. The general rule is that the lamella width is 73 mm.

The use of 100% Rift/ Half Rift material gives the panels a simple, elegant and linear look.

Processing

Furthermore, the solid wood panels are glued with D4 white glue, which is harmless to health and does not produce any vapours. This means that the solid wood panel can be used without any problems in interior design, the contract sector or in furniture construction.

Dimensions

The standard dimensions of the panel are 2970 x 1290 x 20 mm. (Other dimensions on request).

The surfaces of the Echtle three-layer panels are identical to those of the solid wood panels. The top and back layers (each with a thickness of 5.5 mm) are produced from the same raw material. The non-visible centre layers are made of industrial quality fir/spruce.

In contrast to the solid wood panel, the three layers of the three-layer panel are glued together with PU glue. This PU glue hardens when exposed to moisture. Just like the white glue, the PU glue does not release any harmful vapours. The Echtle three-layer board can therefore be used without hesitation in residential and commercial buildings.

The middle layer (fir/spruce) is inserted crosswise and glued. By gluing the longitudinal and transverse layers together, ‘working’, i.e. swelling or shrinkage, is reduced to a minimum. This ensures a high degree of dimensional stability.

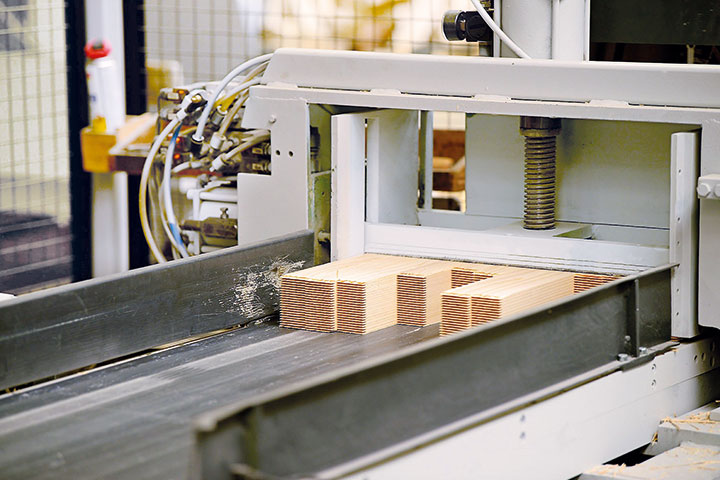

Firstly, the individual lamellas, continuous or finger-jointed, are glued and pressed to form single-layer/solid wood panels. These boards can be produced in different qualities and serve as the top layer of the three-layer board. The top layer is usually also the visible side.

The three layers are glued together with PU glue. PU glue hardens when exposed to moisture and then no longer releases any harmful vapours. The three-layer boards can therefore be used without hesitation in residential and commercial buildings.

The back layer is usually made from finger-jointed lamellas (quality: industrial). However, the backing of the three-layer board can also be manufactured with one of the top layer qualities on request.

After pressing, the three-layer panel is formatted to the finished size in the processing centre. Calibration sanding is then carried out to the appropriate thickness.

Surface

The qualities of the surfaces (top layers)

are identical to those of the solid wood panels:

As standard, the back layer of the

three-layer board is in ‘industrial’ quality.

However, other dimensions and quality

combinations are available on request.

Formats

Standard format of the panel: 2970 x 1290 mm

Standard panel thickness: 20 mm

Possible thicknesses: 17 – 50 mm

We also offer the three-layer board with an all-round groove. The standard size with all-round groove is 2970 x 635 x 20 mm.

With the help of various screw claws, these three-layer boards can be fastened invisibly.

Echtle is involved in the association for the sustainable promotion and conservation of silver fir. Find out more at www.weisstanne.info

The Echtle power plant fulfils the ISO 50.001 standard, a sustainable energy management system.

We are certified with the PEFC seal for wood products from sustainably managed forests.